Floor Systems; we never think about them. Or, at least, we never want to think about them. All floor systems must, at the very least, keep us on the level. They must support their own weight and the weight of our stuff (combined, these are called the ‘dead load’). They must also support the weight of everyone who lives, walks, dances, or jumps on them (this is referred to as the ‘live load’). The floors in The Great Northern Block are designed to support a minimum dead load of 30 pounds per square foot and a live load of 40 pounds per square foot for a total design load of 70 pounds per square foot. Every floor area in the building is designed to bear this total load without deflecting more than 1/480 of the length that portion of the floor spans. That’s a pretty stiff floor. You’ll feel it as soon as you set foot in your new home..

Of course, all our floor systems meet the one-hour fire barrier that is required by code, but our floors can meet this requirement one sided. That is to say, either the ceiling OR the flooring alone can meet the fire separation code. Why?…With this design, one level of our building can be occupied while the level above or below are still being fit up. You’ve maybe never even thought about your floor’s ability to resist fire. The fire chief does. Your insurance company does.

The other major consideration in designing a floor system is to address the way it damps out noise from one level to the next. In multi-family buildings, this aspect becomes very important, so we’ve taken it very seriously.

Floor systems must damp airborne sound waves like music or conversation as measured by their Sound Transmission Class (STC), as well as structurally transmitted waves as measured by their Impact Isolation Class (IIC). Achieving a high STC is more of an issue in wall design as the thick, insulated nature of floor systems already damp airborne sound waves quite well. Floor impacts (ie. high-heeled shoes) are harder to manage. If allowed, impact vibrations can find their way through structural members and resonate into the spaces below. There are several excellent methods to prevent this from occurring and they all involve isolation and mass.

A massive or heavy object won’t transmit the vibrations caused by an impact. Additionally an object that is isolated from the structure with a barrier of flexible material may vibrate, but it won’t transmit those vibrations through the flexible material and into the structure. Put these two concepts together, and you’ll have the basis of a floor system that is effectively absorbs impact vibrations.

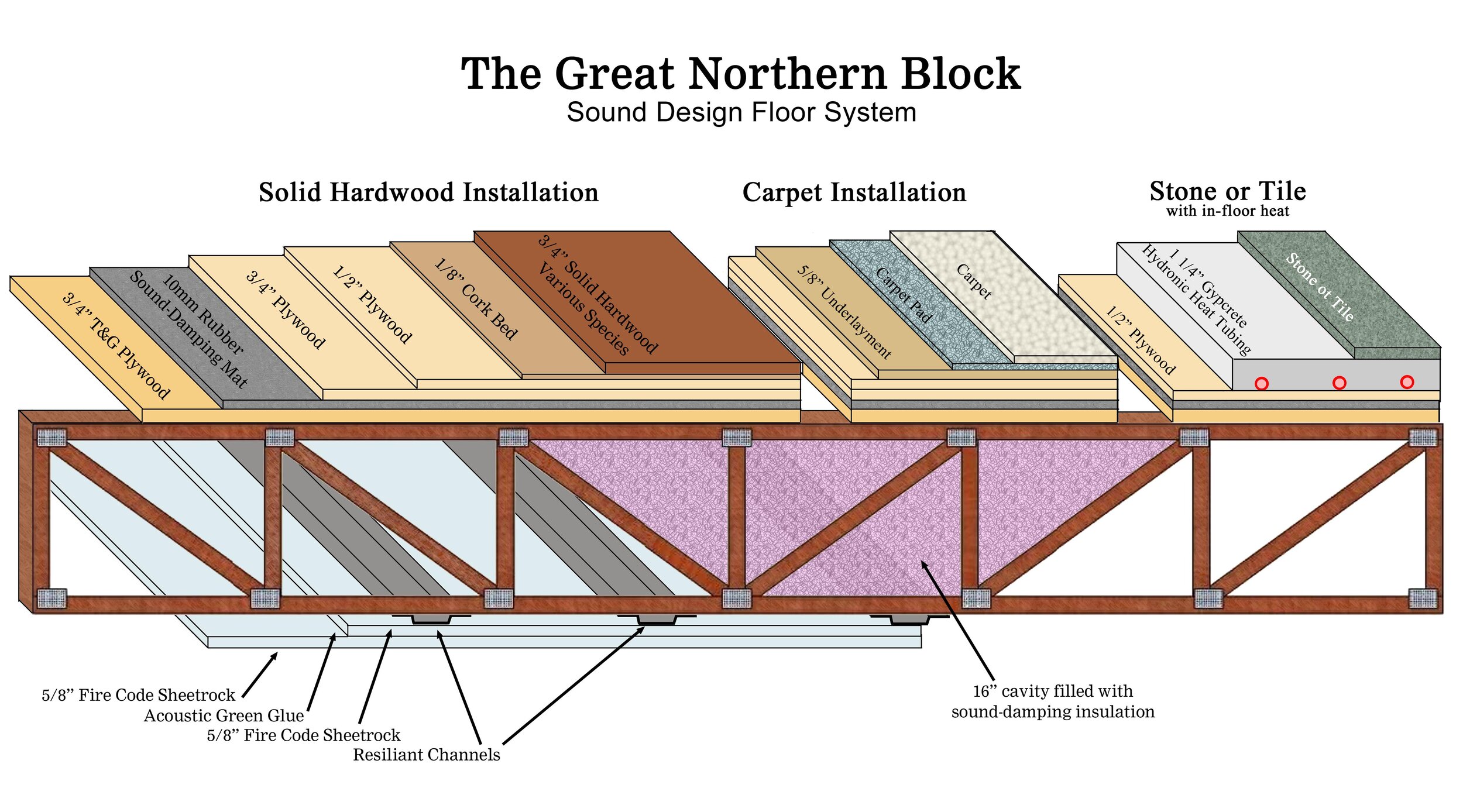

All of the floor systems at The Great Northern Block utilize a mass-isolation hybrid to damp impact-related sound and vibration. Every ceiling is constructed of two layers of 5/8-inch gypsum wallboard (Sheetrock). These layers are fastened together with sound-absorbing glue and then screwed into resilient channels that provide a slightly flexible connection between the wallboard and the structural truss. No fasteners touch both the wallboard and the structural truss (isolation). Two layers of 5/8-inch fire-code Sheetrock weigh 4.6 inches per square foot. That’s about 800 pounds for a typical bedroom ceiling (mass). The ceiling system alone is quite effective as absorbing any sound that is either transmitted through the joist cavity or vibrations that are transmitted via the joist itself. And every joist cavity is filled with 16 inches of insulation to eliminate airborne sounds. It’s above the joists that we are taking steps to eliminate the impact-created structural vibrations.

Remember, isolation and mass are the keys to impact sound damping.

No one cares much about the finish of a ceiling. A little texture….or not. A splash of paint and nobody will ever notice. Floor finish, however, is a different matter. The floor systems at The Great Northern Block are designed to give homeowners a wide range of finished-floor choices all of which will provide a high level of sound damping.

A 3/4-inch tongue and groove plywood floor is screwed directly to the structural trusses. Then, a 10-millimeter rubber sound isolation mat is glued to the plywood floor. This mat extends wall-to-wall and separates the remaining floor layers from the floor trusses and structural members of the walls (isolation). This system is called a floating floor, and builders have been using it for years, but they often get the mass part wrong. If a builder installs a floating 3/8-inch hardwood laminate over a layer of cork, they’ve accomplished the isolation part, but the floor weighs less and one pound per square foot. We’ve likely all walked on one of these light-weight, ‘clickety-clack’ laminate hardwood floors. At The Great Northern Block, we’ve bulked it up a bit.

If the finished floor is to be traditional ¾-inch solid hardwood, the floating floor will consist of more than an inch of multi-layer plywood fastened together, a thin layer of cork, and, finally, the hardwood. The hardwood will be nailed through the cork and into the inch-plus of plywood, which ‘floats’ on the rubber mat. No fasteners will pass through the rubber mat into the base plywood or the joists. This floor will float in isolation and weigh over seven pounds per square foot. That’s more than one thousand pounds for a typical bedroom.

Carpet and vinyl flooring will receive a similar treatment, but an additional layer of sub flooring will make up the difference in thickness.

Every area of the building finished with tile or stone will feature in-floor heat. These areas will feature the same base plywood flooring and the same 10-millimeter sound-damping mat. Next, a thin layer of plywood will fasten the hydronic heating tubes to the mat. Those tubes are encased in 1 ¼-inch layer of Gypcrete. Finally, the finish layer of stone or tile will bring the floor up to level. These areas will have a floating weight around 16 pounds per square foot, a full ton for a nice-sized bathroom.

A few additional measures complete the system. Floating floors are permitted to expand and contracts without contacting the wall structures. Wall boards and baseboard will attach only to the resilient wall materials. A flexible sealant joins the trim to the floating floor.

We’ve taken these concepts through the roof. As many as six inches of hard insulation will aid in the isolation and the roof will have 2.4-inch thick, 9.4-pounds-per-square-foot rubber paver deck. Overall, the entire building will comprise over 350,000 feet of floor systems about three times more per square foot than in typical homes.